Everything About Membrane Change: Comprehending Its Layout and Capability

When you assume about the control interfaces in modern-day gadgets, membrane layer switches often come to mind. Let's discover what sets membrane layer changes apart from other control systems.

What Are Membrane Layer Switches?

Their smooth nature makes them easy to clean and resistant to dust and moisture, an important attribute in lots of environments. Membrane buttons can also be personalized concerning form, size, and graphics, allowing suppliers to develop one-of-a-kind interfaces tailored to certain items. Plus, they're light-weight and thin, which assists in decreasing the general mass of tools. Generally, membrane buttons play a considerable function in improving customer experience across a broad array of applications.

Exactly How Membrane Layer Switches Over Work

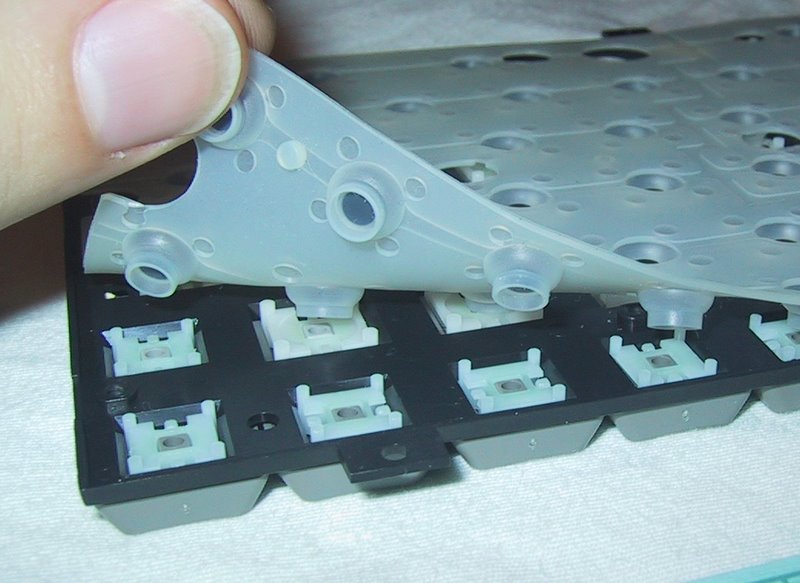

When you push a secret on a membrane layer button, it triggers a straightforward yet efficient device. membrane switch manufacturer. The top layer, frequently made of flexible material, pushes down onto a conductive layer underneath it.

You'll see that the tactile feedback varies based on the switch style, providing either a soft click or a much more noticable response. When you launch the secret, the membrane go back to its initial placement, resuming the circuit and stopping the signal. This procedure happens nearly instantaneously, ensuring a responsive individual experience.

Membrane buttons are popular as a result of their longevity and resistance to dirt and wetness, making them optimal for different applications, from family home appliances to medical gadgets. Recognizing this procedure aids you appreciate their widespread usage.

Trick Parts of Membrane Layer Buttons

Understanding the essential elements of membrane switches is fundamental for understanding their performance and layout. The protective layer guards against environmental factors and use, expanding the button's life expectancy. By recognizing these components, you'll get insight right into how membrane layer switches operate and their importance in different applications.

Materials Used in Membrane Change Style

The efficiency and sturdiness of membrane switches heavily rely on the materials utilized in their style. You typically experience polyester and polycarbonate as primary substratums as a result of their outstanding toughness and versatility. These products resist scratches and chemicals, making them excellent for demanding settings.

The conductive layers typically make use of silver or carbon, picked for their integrity and conductivity. membrane switch manufacturer. Silver gives remarkable performance, while carbon is an affordable choice. For the overlay, you might consider a matte or shiny finish, relying on your visual demands and user experience

Adhesives play an essential Check Out Your URL duty as well; they bond layers safely and guarantee long life. Make specific to select adhesives that endure environmental aspects like temperature level and humidity. Finally, do not forget the significance of a good printing strategy for graphics, as it boosts both functionality and aesthetic appeal. Choosing the right materials will certainly guarantee your membrane layer switch stands the examination of time.

Style Considerations for Membrane Switches

While developing membrane layer buttons, it's important to take right into account numerous factors that influence their capability and customer experience. Begin by concentrating on the layout and switch size; make particular they're intuitive and very easy to browse.

Don't neglect the graphic style; clear labeling and color comparison are significant for visibility. Validate your layout suits ecological factors, like wetness or temperature level variants, which can influence performance. Keep in mind the relevance of testing prototypes with genuine individuals to gather feedback and make essential modifications. This iterative procedure helps you fine-tune the style, validating it satisfies both useful and visual requirements properly. By meticulously considering these aspects, you'll develop a membrane layer switch that improves usability and fulfillment.

Applications of Membrane Switches

Membrane layer buttons are versatile elements located in different applications, from industrial equipment to customer electronic devices. You'll see their effect in machines that call for sturdy interfaces and in tools that profit from sleek styles. Recognizing these applications aids you appreciate the capability and usefulness of membrane switches in day-to-day modern technology.

Industrial Equipment Use

When you're looking to improve the functionality of industrial tools, membrane layer buttons supply a trustworthy service that incorporates sturdiness with straightforward layout. These switches are ideal for severe atmospheres, supplying resistance to dirt, moisture, and chemicals. Embrace membrane layer buttons to improve your procedures and improve general performance.

Customer Electronic Devices Integration

In the domain of consumer electronic devices, membrane layer switches play a necessary role in boosting customer communication and gadget performance. Membrane buttons likewise assure longevity and resistance to dirt and moisture, expanding the life expectancy of your electronics. By selecting membrane buttons, you enhance not simply the capability however additionally the style of your devices, making day-to-day interactions smooth and pleasurable.

Advantages and Disadvantages of Membrane Layer Switches

While membrane layer switches supply a range of benefits, they also come with some drawbacks that you need to consider. One considerable benefit is their small style, making them suitable for space-constrained applications.

Membrane layer buttons can have a additional hints shorter lifespan contrasted to mechanical switches, especially under hefty usage. They can additionally be less responsive, which could affect individual comments throughout procedure. Stabilizing these pros and cons will help you establish if membrane layer buttons are the right fit for your project.

Regularly Asked Concerns

The Length Of Time Do Membrane Switches Generally Last?

Membrane he said layer switches generally last between 5 to one decade, depending on use and ecological conditions. You'll wish to evaluate variables like wear, exposure to dampness, and temperature fluctuations to gauge their long life properly.

Can Membrane Layer Changes Be Custom-made for Details Layouts?

Yes, you can tailor membrane layer switches to fit details styles (membrane switch manufacturer). You'll have the freedom to choose colors, shapes, and formats that match your task's requirements, ensuring they blend effortlessly with your general aesthetic

What Is the Cost Array for Membrane Layer Switch Manufacturing?

The expense range for membrane switch production typically drops in between $1 and $10 each, depending on variables like layout complexity, amount, and materials. You can get quotes from suppliers to locate the most effective alternative.

Are Membrane Changes Water-proof or Immune?

Membrane switches can be designed to be water-proof or resistant, depending upon products utilized and building and construction methods. If you need them for damp environments, assure you define those requirements during the style procedure.

Exactly How Do Membrane Switches Over Contrast to Conventional Switches?

Membrane layer switches are generally thinner and extra adaptable than typical buttons, offering a sleek style. They're typically easier to clean and integrate, yet could not supply the tactile comments you're made use of to with mechanical alternatives.

Conclusion