Picking the Right Bearing Bushing for Optimum Performance

On the planet of equipment and industrial applications, the importance of selecting the best bearing bushing can not be overemphasized. Bearing bushings play an important function in making certain optimum efficiency and durability of numerous mechanical elements. Nevertheless, with a wide array of choices available in the marketplace, choosing the perfect one can be a daunting job. From considering different elements such as lots rate, capacity, and operating problems to understanding the importance of appropriate lubrication and upkeep, there are a number of aspects to delve into. In this discussion, we will certainly check out the various kinds of bearing bushings, essential elements to consider, and useful ideas for installment and upkeep, all bring about the ultimate goal of achieving optimal performance.

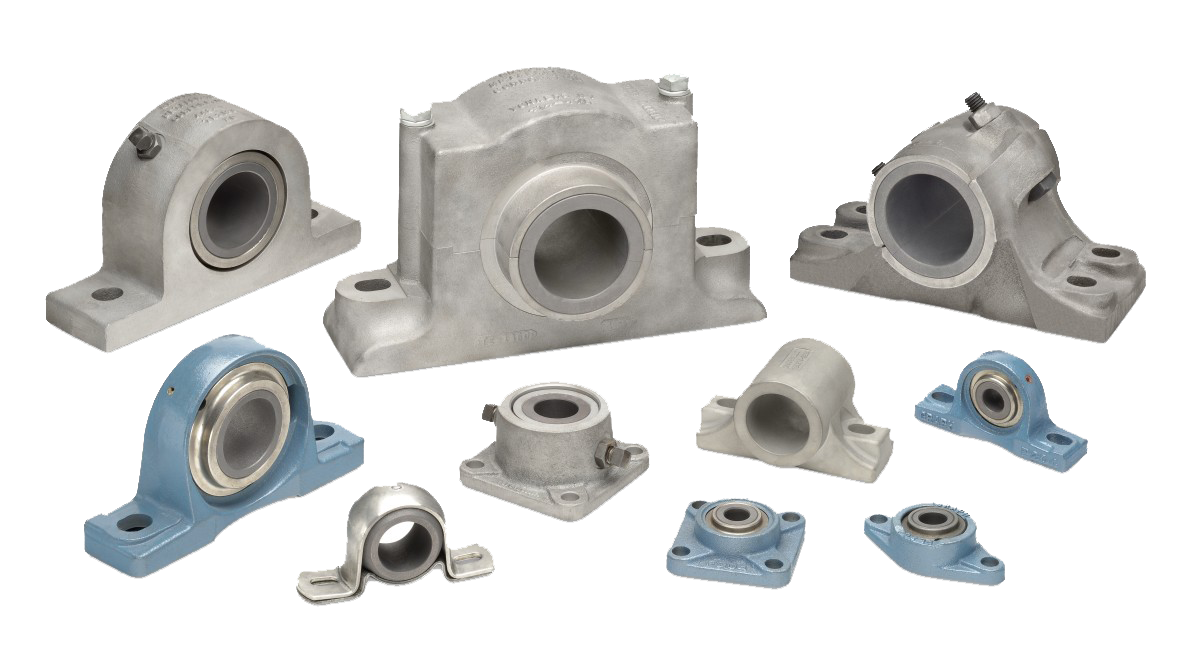

Kinds Of Bearing Bushings

There are numerous different kinds of birthing bushings readily available for different applications. These bushings give support and decrease rubbing in between moving parts in equipment and devices. One typical kind of bearing bushing is the plain bearing bushing. This type of bushing consists of a cylindrical sleeve constructed from a low-friction material, such as bronze or plastic. Plain bearing bushings are excellent for low-load and low-speed applications, as they supply excellent resistance to use and can take care of light to modest radial and axial lots.

One more kind of bearing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which aids to correctly place and align the bushing within the real estate.

Variables for Factor To Consider

When choosing the appropriate bearing bushing, there are numerous crucial elements to consider. These aspects can significantly influence the efficiency and longevity of the bushing, in addition to the general efficiency of the machinery in which it is mounted.

One critical variable to consider is the operating problems in which the bearing bushing will be utilized. This consists of aspects such as temperature, moisture, and the presence of harsh materials. Different materials have varying resistance to these problems, so it is necessary to choose a bushing that can stand up to the specific atmosphere it will certainly be subjected to.

Another variable to think about is the lots and speed needs of the application. The bearing bushing ought to be able to handle the expected lots and run efficiently at the called for speed. Failure to select a bushing that meets these specs can cause premature wear and failing of the bushing.

In addition, the compatibility of the bearing bushing with the mating surface area need to be evaluated. The bushing material ought to work with the shaft or housing material to reduce friction and wear. It is likewise crucial to think about the lubrication demands of the bushing and make sure that the suitable lubricating substance is used.

Finally, the price and accessibility of the bearing bushing should be taken into account (bronze bushing). While it is essential to select a bushing that fulfills the required requirements, it is also essential to think about the spending plan and the availability of the chosen bushing

Value of Proper Lubrication

Proper lubrication is crucial for the optimal efficiency and longevity of a bearing bushing. A bearing bushing is an essential component in various applications, varying from automobile engines to industrial machinery. It assists reduce basics rubbing and wear in between moving parts, ensuring smooth procedure and avoiding premature failure.

Lubrication plays an important duty in keeping the health of a bearing bushing by decreasing rubbing and warm generation. By creating a slim film of lubricating substance in between the bearing surfaces, it minimizes call and permits for smooth motion. bronze bushing. This aids to stop excessive damage, making sure that the bearing bushing can endure the high lots and speeds it might experience

Furthermore, appropriate lubrication also assists to dissipate warmth produced throughout operation. Too much heat can create the lubricant to damage down, leading to minimized lubricating residential properties and potential damages to the bearing bushing. By selecting the best lubricant and guaranteeing appropriate lubrication intervals, the temperature can be kept within appropriate restrictions, enhancing the general efficiency and long life of the bearing bushing.

It is necessary to take into consideration different elements when choosing the proper lubricating substance for a bearing bushing, such as operating conditions, speed, temperature level, and tons (bronze bushing). Furthermore, normal upkeep and tracking of lubricant levels are critical to make certain that the bearing bushing is effectively oiled throughout its solution life

Installation and Maintenance Tips

To ensure optimum performance and longevity of a bearing bushing, appropriate setup and upkeep are vital. Incorrect installment can lead to imbalance and premature wear, reducing the total performance and life expectancy of the bushing.

Furthermore, routine cleaning is needed to get rid of any type of dirt, particles, or impurities that might have built up on the surface of the bushing. This can be done making use of a soft towel or brush, making sure not to scrape or damage the bushing.

Choosing the Right Provider

Choosing the appropriate distributor for your bearing bushing is an important choice that can significantly impact the performance and reliability of your tools. A great post to read reliable provider will certainly not only give you with premium bearing bushings however additionally provide excellent customer assistance and technical experience. When choosing a supplier, there are several aspects to think about.

First of all, seek a vendor that concentrates on birthing bushings and has a tested record in the sector. They must have a large range of products to fulfill your particular demands and be experienced concerning the different sorts of bushings readily available.

Secondly, consider the distributor's track record and client testimonials. Try to find testimonies from various other customers to evaluate their satisfaction with the provider's services and products. A trustworthy vendor will have positive responses and a solid credibility in the market.

Thirdly, review the distributor's manufacturing capabilities and quality assurance procedures. Ensure that go they stick to rigorous quality criteria and have durable testing procedures in position to ensure the reliability and longevity of their products.

Lastly, take into consideration the supplier's prices and distribution terms. While expense is an important aspect, it needs to not be the single determining element.

Conclusion

In verdict, choosing the best bearing bushing is important for achieving optimum efficiency. In general, making informed choices in these areas will certainly contribute to the general success and performance of the bearing bushing.

One common type of birthing bushing is the plain bearing bushing.Another type of birthing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which helps to correctly position and straighten the bushing within the real estate. Failing to choose a bushing that fulfills these specifications can result in early wear and failure of the bushing.

Choosing the appropriate supplier for your bearing bushing is an important choice that can significantly impact the efficiency and reliability of your devices.